Nebraska SBDC Blog

- UNO

- College of Business Administration

- Nebraska Business Development Center

- Nebraska SBDC Blog

- Additional Resources

- SBDC Blog

- Staff Directory

- NBDC News Center

Job Shop Misconceptions: Making the Case for Lean

Posted by Renee Held on Aug 09, 2021 10:07:30 AM

In my conversations with owners of job shops and contract manufacturers about their business needs, the “Lean Enterprise” topic usually comes up. Many owners believe Lean techniques are for high volume manufacturers or highly repetitive manufacturers only; they tell me that Lean is of no benefit to their operations. They affirm that they are “Lean” already— because they have the right number of people to get the work done for their orders. I was curious about what influenced their thinking about Lean, so I pursued this topic further by interviewing company owners. Before continuing, I want to discuss what “bias” and “pattern” means in the context of this paper. Bias causes us to respond without questioning all the facts, or may be caused because we don’t understand. People tend to put the unfamiliar or unknown into the context of what is commonly understood or experienced. In the patterned way of thinking, we base our responses only on what we already know. I have a personal example of “bias” and “patterned” perceptions. It begins with a conversation with my four-year-old grandson.

comes up. Many owners believe Lean techniques are for high volume manufacturers or highly repetitive manufacturers only; they tell me that Lean is of no benefit to their operations. They affirm that they are “Lean” already— because they have the right number of people to get the work done for their orders. I was curious about what influenced their thinking about Lean, so I pursued this topic further by interviewing company owners. Before continuing, I want to discuss what “bias” and “pattern” means in the context of this paper. Bias causes us to respond without questioning all the facts, or may be caused because we don’t understand. People tend to put the unfamiliar or unknown into the context of what is commonly understood or experienced. In the patterned way of thinking, we base our responses only on what we already know. I have a personal example of “bias” and “patterned” perceptions. It begins with a conversation with my four-year-old grandson.

Monkeys on the Trampoline

Recently, when I answered the phone, I was greeted by a cheery small voice wishing me “Happy day, Grandma!” When I asked my grandson Liam what he was doing, he launched into an excited story about how he was in the mountains— In today’s extremely competitive business environment, a focus on continuous improvement through the lean process can make a huge difference in the financial success and growth of a business. that there were bears and monkeys jumping on a trampoline into water. At this point, I began to wonder what was going on. I knew his family had a trampoline in their backyard in South Carolina, but no mountains, bears, monkeys or swimming pools near his home. My daughter took the phone to explain that they were in the mountains on a mini-vacation and were staying in a cabin with a hot tub. I’m guessing that Liam, who had just visited the zoo, reasoned (bias?) that since the animals he saw there all lived in wild places, they must live in the Tennessee mountains, too. This was probably the first time that he had seen a covered hot tub, so he described to me something he already knew (patterns)—his trampoline at home. How he made the leap to monkeys jumping on the trampoline, I mark up to the imagination of a four-year-old!

Not Just for Automobiles

Two days after this conversation, I called the president of a mid-sized manufacturing plant to ask if he would be interested in participating in Lean training offered by the Nebraska Business Development Center. He declined, stating that his company is a job shop where they make custom products for their customers and Lean doesn’t really apply … that Lean improvement is for repetitive manufacturing.

Since his company makes custom products that are rarely repeated, he does not consider Lean. My guess is that when this president heard about Lean techniques, they were associated with automobile manufacturing—which, in fact, uses highly repeatable processes and has successfully implemented Lean improvements. He had developed a personal opinion which was confirmed by something he read or heard from others. To begin transforming his thinking, I asked if the company buys brand new equipment each time it makes a unique product. He responded no—equipment does not change, even when the products are custom. Like his equipment, I said that Lean is about looking at processes, not products. I suggested he take a look at each of the individual processes used to make his custom products and follow each step to identify the process wastes that may be happening. I then, challenged him to go to his shop and watch people work— to ruthlessly view from his customers’ perspective and ask the question, “Would I want to pay for what is being done right now?” If he sees activities that his customer would not want to pay for, then he is a candidate for Lean and he might want to consider the possibilities and change his mind about implementing Lean techniques. The challenge also included that I would call him back in a month to get a report of his findings! By this time, the president was beginning to understand that work patterns of his people might be causing inefficiencies. Even though his products are all different, similar or same processes are used to manufacture them. Understanding how some work patterns add waste to the final product even in job or custom manufacturing is the first steps to identify wastes are occurring and then work on eliminating these non-value added steps. I was able to shift his original bias against Lean, nudge him to explore work patterns at his company and recognize that Lean can be beneficial for a job shop.

Achieving Benefits of Lean in Job Shops

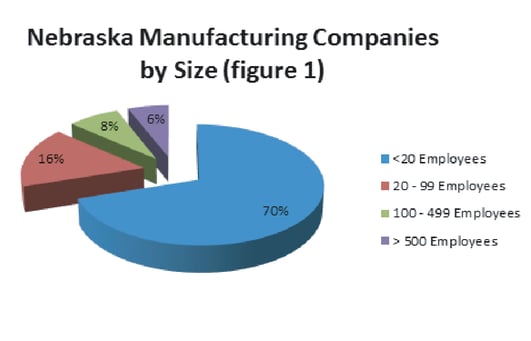

I have worked with smaller job shops that have implemented Lean and have successfully found the benefits are achievable. Lean techniques will work in any organization large or small; performing most any process. In Nebraska, over 85% of the manufacturing firms have fewer than 100 employees. These companies have the greatest potential for growth and increase revenue by becoming more efficient at what they do. (see Figure 1)

Larry Fast, the founder and president of Pathways to Manufacturing Excellence, offers a few suggestions to understand the importance of implementing Lean techniques in low-volume, job shop environments: In my experience, there is always a link between lack of throughput and poor quality. Poor delivery performance is also negatively affected by poor quality and the unreliable production flow. So significantly improving quality will cause the manufacturing leaders to see improvement in all three areas they’re concerned about. Once they understand that, why would they not want your help? What they will want instead is to know what you need from them to accelerate improvements. Ask the manufacturing leaders to meet with and communicate to the operators why significant improvements are important and how they can help solve customer and business problems. Offer to be a part of the meeting and share the project(s) that will be the starting point to getting much better. For example, does communication on the state of the business happen regularly? If it does not, then leadership isn’t informing the operators about poor plant performance. They will not know how the plant is doing on key metrics such as quality, delivery, customer service and cost. All employees need to know when the plant is winning and when it is losing. Which is more important—quality or delivery? If you were a customer, how would you answer that question? Whether you are in low- or high-volume production, you don’t have to choose. If you have robust processes backed up by robust maintenance, training, etc., you will get both. That’s what the customer expects and is also what you should expect.

Even small operations have “bias” — a belief that everyone has the same comprehensive understanding of the work projects. Yet, in order for this to be true, there must be a method for regular communication about the status of the project, what needs to be accomplished each day, and which needs more attention—quality or delivery. To improve a manufacturing system, start by asking people who have downtime between steps to do a 5S (workplace organization) of their areas, begin to standardize the workshop, or learn new skills. The end goal is to operate your business in an environment of zero waste by reducing or eliminating work the customer doesn’t want to pay for:

- Over production—producing more than needed by customers or next operation

- Inventory—material sitting anywhere within the value stream is non-value added

- Waiting—downtime within the process where value-added activity has stopped

- Motion—any physical movement where transformation is not happening

- Transportation—movement of product or material between or among operations

- Excessive processing—additional run time; extra handling

- Defects—any process, or service that fails to meet specifications creating rework.

Small Business, Small Margin for Error

Discussing Lean manufacturing in small shops, Leon Milobar, district director, U.S. Small Business Administration, said, “In today’s extremely competitive business environment, a focus on continuous improvement through the Lean process can make a huge difference in the financial success and growth of a business. Small businesses do not have a significant margin for error and therefore have more need to reduce waste—which can be a significant outcome of applying the Lean process and continuous improvement. Other outcomes include satisfying customer needs, improving operations, engaging employees, and saving costs.”

As a Lean consultant at NBDC, I challenge clients to reflect on their bias and patterns of thinking. I ask them to answer the following tough questions about their processes:

- Is the customer willing to pay for what I am doing right now?

- Is the work that I am doing right now transforming the product or service that customer desires?

- Is the work that I am doing right now, being done right the first time?

For my 4-year-old grandson, I believe his bias will change and patterns of thinking will broaden as he experiences more of what life has to bring. He will learn more about the world, but hopefully, he will not lose his keen imagination and ability to share wonderful stories! If you have any questions about why Lean management is right for your organization, give me a call. (I’ll try not to talk about monkeys or trampolines.)

This blog was originally published as a whitepaper for Nebraska Business Development Center. To view the original whitepaper, click here.

Posts by Tag

Contact Us

- Administrative Office

- 200 Mammel Hall

- 6708 Pine Street

- Omaha NE 68182

- 402.554.NBDC (6232)

- nbdc@unomaha.edu

- Consultant Directory